At MY Polymers – The Low Refractive Index Company, we do our best to be responsive to our customers.

Any technical issue which arises either before or after you get our materials and start working with them can be discussed directly with our technical staff.

Simply press the red button marked ASK A TECHNICAL QUESTION on the right top and you’ll be asked to describe the issue at hand.

Some technical questions and issues tend to appear more frequently than others.

MAJOR TECHNICAL ISSUES

RELEVANT PUBLISHED PAPERS

TECHNICAL SUPPORT VIDEO

UV curing in an Inert Atmosphere

This video shows MY Polymers low refractive index coating OF-133, being cured inside a Nitrogen chamber on an optical fiber drawing tower. The fiber, that was just coated by the OF-133 is entering the UV curing section. UV curing is done in such inert conditions to minimize Oxygen competition.

Low Refractive Index Demo

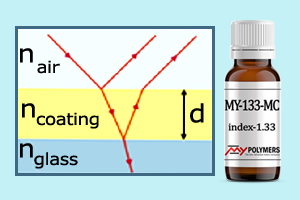

This video demonstrates the MY-133-V2000 index of 1.33, which is identical to water. The fish was produced by UV curing inside a transparent mold with small grooves, to create opacity that enhances the optical effect.

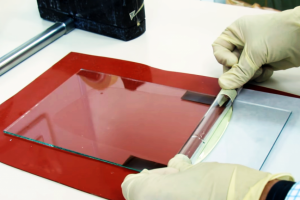

How to coat

This video shows how to produce an even, thickness controlled coating, using simple means

Contact Details

- [email protected]

- +972-8-9350101

- +972-8-9351767

- 3 Golda Meir St., Ness Ziona, Israel